Notre jeune entreprise a développé des équipements innovants pour le recyclage des anciens pneumatiques en produisant des poudres de haute qualité sur base de composés caoutchoucs. Notre business model est basé sur la vente d’usines clés en main pour notre recycling partners présents à l’international.

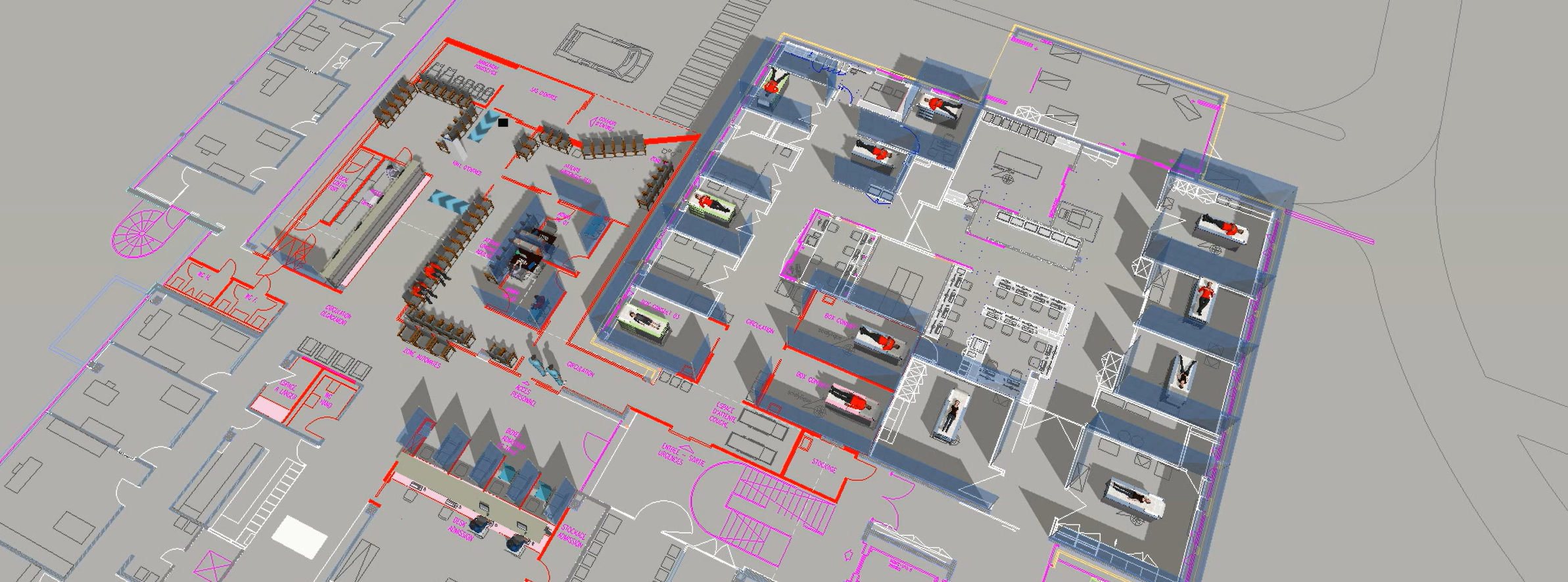

Dans ce cadre nous avons approché la société Procsim pour nous permettre de modéliser nos lignes de production et d’avoir un outil 3D flexible et dynamique pour pouvoir étudier les différents scénarios d’implantation, chaque usine ayant des propres contraintes en termes de capacités, bâtiments, sourcing et stockages des pneumatiques, sécurité, etc. Nous avons tout particulièrement apprécié les compétences de toute l’équipe Procsim dans l’accompagnement sur nos projets complexes et leur force de proposition et de conseils. Nous avons maintenant mis en place une bibliothèque de solutions industrielles qui nous permet d’optimiser les implantations et aussi d’anticiper les évolutions futures de ces lignes de production et de pouvoir communiquer efficacement avec nos clients par visualisation 3D et réalité virtuelle également. La prochaine étape sera d’intégrer la gestion dynamique des flux selon les contraintes multiples de nos process et le dimensionnement des capacités et buffers pour optimiser les productivités de nos lignes.

L’expertise de l’équipe Procsim est clairement un atout pour notre société et une forte valeur ajoutée pour permettre d’anticiper les situations et gérer au mieux les risques relatifs et nous nous réjouissons de poursuivre notre collaboration.

Notre entreprise a intégré en son sein une nouvelle façon de concevoir ses machines en effectuant un virage technologique tout à fait novateur. La nouveauté s’accompagne toujours de risques et d’inconnues qu’il faut prévoir, maîtriser et minimiser. Une étude de la capacité de production de nos nouvelles lignes s’imposait.

ProcSim nous a accompagnés du début à la fin du projet de modélisation de notre nouvelle ligne. Le projet a été présenté à ProcSim qui a parfaitement compris notre problématique et nos attentes. Il s’en est suivi une modélisation novatrice en utilisant l’outil de simulation FlexSim pour répondre à notre demande et à la mise en place d’un modèle d’optimisation. ProcSim a su nous accompagner dans notre projet en effectuant les modélisations et optimisations attendues et finalement répondre à nos interrogations. La qualité de nos échanges avec l’équipe de ProcSim, l’intérêt démontré pour nos activités, ainsi que les challenges soulevés tout du long du projet m’ont particulièrement impressionné. De plus, des recommandations pertinentes qui sortaient de la demande initiale de notre projet ont également été apportées.

Pour toutes ces raisons, je recommande ProcSim sans aucune réserve, à toute entreprise ou personne qui souhaite étudier et optimiser ses lignes de productions ou de gestions de flux de matière et d’information.

We have engaged ProcSim in a Warehouse transformation Project aimed at optimizing the efficiency of the warehouse processes. Through a simulation model of automation for put away, replenishment and staging products, ProcSim has helped us to better understand the nature of constraints we are facing today mainly at the End of Lines with pre-call and queueing of vehicles. During second step of the simulation, they have analyzed our future layout developed by the Design Team and three alternative automation solutions’ suppliers. They built some custom logic into the model to analyze the error rate of vehicles and the mean time to repair errors to understand how many vehicles are needed to run the system. Results of the different scenarios assisted in understanding the changes that need to be made to the layout and design of the automation system within the warehouse.

Our collaboration with ProcSim started few years ago in the area manufacturing flows simulation, and we have been always pleased with the level of professionalism and tangible business value Procsim team brings to us. In addition, we highly appreciate the agility of ProcSim to respond in an effective way to our various requests. In Nestlé, we consider ProcSim a key partner of our Digital manufacturing.