Industry

The digital twin to improve industrial performance.

The industry is characterized by intense international competition. Additionally, traditional manufacturing and production methods are disappearing to make way for more automation and more digitized processes. This leads its players to constantly innovate and improve their current systems to remain competitive.

ProcSim has carried many F&B, Luxury Watch, Fragrances & Flavors, and many more companies to maintain their competitive edge by helping them digitize, automate, and improve their production lines, workshops, manufacturing and packaging plants as well as their logistics warehouses.

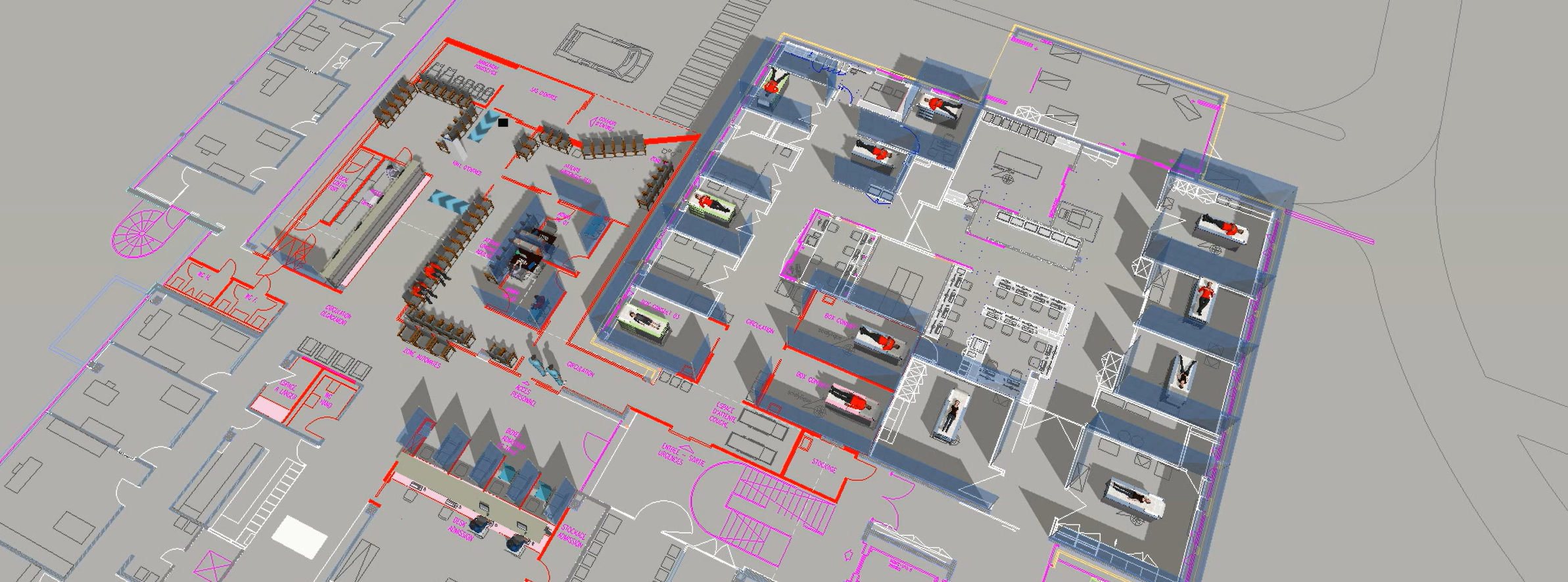

A digital twin is the digital representation of a tangible structure or environment, such as a production line, storage platform or building. It is more of a digital model than a traditional 3D model. It’s actually a common data reference created during the planning phase of a project that spans the entire life cycle of an asset, from design, to manufacturing and construction, to installation and to operation and maintenance, but also its future use or reuse.

Unlike models that gather static data, digital twins are dynamic and “living” structures that evolve in real time. These clones learn, update and communicate with their physical models by exchanging data throughout their life cycle. Armed with these dynamic simulations, users can anticipate problems before they arise, imagine new possibilities, and plan for the future.